Getting My Roar Solutions To Work

( Area 0, 1, or 2). This variation will certainly additionally affect the resourcing needs for work preparation. Once Great deals are specified, you can create tasting plans based on the sample dimension of each Whole lot, which refers to the variety of random tools items to be examined. To figure out the needed example dimension, two elements need to be reviewed: the dimension of the Whole lot and the category of assessment, which suggests the level of effort that ought to be applied( decreased, regular, or increased )to the evaluation of the Lot. By incorporating the category of inspection with the Whole lot size, you can then establish the appropriate denial requirements for an example, indicating the permitted variety of faulty things located within that sample. For more information on this procedure, please refer to the Energy Institute Guidelines. The IEC 60079 common suggests that the maximum interval in between examinations ought to not exceed three years. EEHA examinations will certainly likewise be conducted beyond RBI projects as part of arranged maintenance and tools overhauls or repairs. These inspections can be attributed toward the RBI example dimensions within the affected Whole lots. EEHA evaluations are conducted to recognize faults in electrical equipment. A heavy scoring system is important, as a single piece of equipment might have numerous mistakes, each with varying degrees of ignition risk. If the mixed score of both examinations is less than two times the fault rating, the Lot is deemed acceptable. If the Whole lot is still considered inappropriate, it must undertake a full evaluation or validation, which might cause stricter inspection procedures. Accepted Whole lot: The sources of any kind of faults are recognized. If a common failing mode is located, additional devices may need inspection and fixing. Faults are identified by seriousness( Security, Integrity, House cleaning ), ensuring that urgent problems are assessed and dealt with immediately to mitigate any kind of influence on security or procedures. The EEHA data source ought to track and tape-record the lifecycle of mistakes in addition to the restorative actions taken. Carrying out a durable Risk-Based Examination( RBI )method is crucial for guaranteeing conformity and security in taking care of Electric Devices in Hazardous Locations( EEHA). Automated Mistake Rating and Lifecycle Administration: Effortlessly manage faults and track their lifecycle to enhance inspection accuracy. The introduction of this support for risk-based examination further reinforces Inspectivity's position as a best-in-class solution for governing conformity, in addition to for any asset-centric evaluation use case. If you have an interest in finding out more, we welcome you to ask for a demonstration and discover exactly how our service can change your EEHA administration procedures.

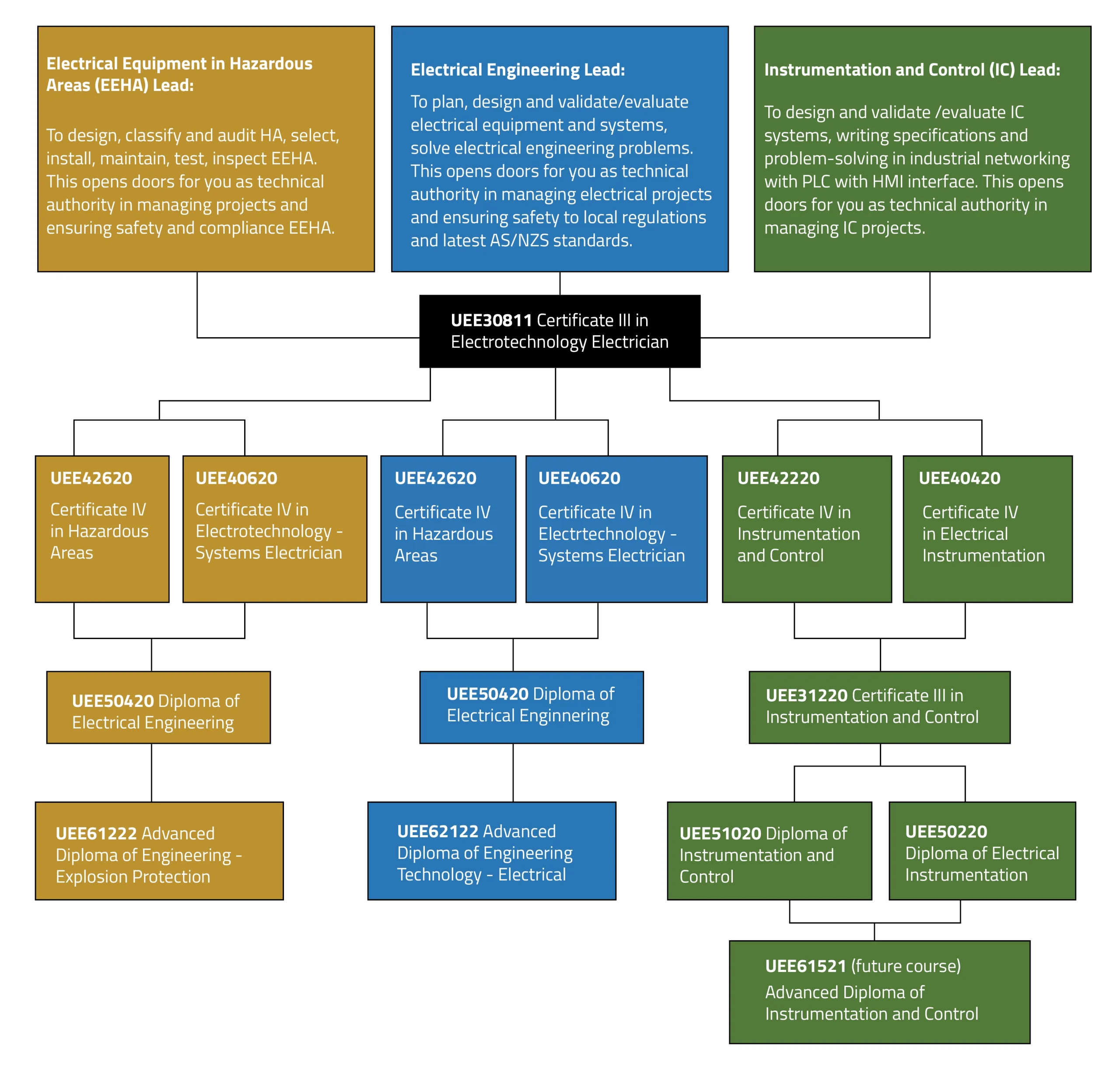

With over 10 years of mixed Ex experience (IECEx/ATEX, EEHA), Saipex started to advertise the importance of capability of all personnel associated with the Hazardous Location area in 2019. In 2021, our partnership with IndEx and Tech Skill International (TSI) marked a milestone in the Saipex road to proceed Ex renovation.

Roar Solutions Fundamentals Explained

In terms of explosive risk, an unsafe area is an atmosphere in which an eruptive atmosphere exists (or might be anticipated to be present) in quantities that need unique precautions for the construction, installment and usage of tools. In this article we discover the obstacles dealt with in the workplace, the danger control procedures, and the called for competencies to function securely.

It is a repercussion of contemporary life that we make, keep or deal with an array of gases or fluids that are deemed combustible, and a variety of dirts that are deemed flammable. eeha certificate. These substances can, in particular conditions, create explosive environments and these can have significant and heartbreaking consequences. Many of us are acquainted with the fire triangular eliminate any kind of among the three aspects and the fire can not occur, yet what does this mean in the context of harmful locations? Read Full Article When breaking this down into its simplest terms it is basically: a mix of a certain amount of launch or leakage of a particular compound or material, blending with ambient oxygen, and the visibility of a source of ignition.

This is then validated through examination and screening and is maintained throughout the life of the setup by using the appropriate upkeep methods, supplemented by routine evaluation. When all these procedures are taken, they need to also be recorded. The confirmation file includes info such as the unsafe area classification illustration, manufacturers' paperwork, tools accreditation, design drawings and computations, inspection documents, and documents of an individual's competency and continuing specialist development (CPD), such as through ECA's eCOMS software program.

The Best Strategy To Use For Roar Solutions

It is imperative that trainees recognize and have a complete knowledge as to exactly what comprises a dangerous location. The pupil should likewise recognize why training is necessary before trying to tackle work or specifying devices into an unsafe area. These areas are likewise understood as identified locations and are defined as areas which have a high possibility of a surge due to the possible existence of flammable gases, vapors, dusts etc.

Industries which contain harmful locations are currently requiring that electric employees that are defining or functioning in these locations need to have an unsafe location certification that considers them experienced. Jobs in these sectors are really gratifying so you need to be prepared. To meet this demand for the sector, nationally recognised training in Certificate IV in Hazardous location Electric and EEHA training on the growth of skilled specialists.

The Of Roar Solutions

Technology Abilities Australia is a Registered Training Company giving you with the most cost effective and quickest means in obtaining your certification - eeha training. Our trainers are market certified and have a number of years of procedure experience. Our training courses have actually assisted thousands of individuals from company supervisors to daily staff members in obtaining a strong hang on this not so difficult yet high threat training

The training also consists of recognizing the harmful locations, resources of explosion and the residential properties of harmful products along with the responsibilities and features of all celebrations, policies, systems, standards and practice codes attached to harmful areas. We offer instrumentation and dangerous area remedies that are in compliance to newest AS/NZS and international sector requirements.

Comments on “Getting My Roar Solutions To Work”